NASA is starting to remove Discovery's three liquid-fueled shuttle main engines today so a faulty turbopump can be swapped out.

NASA is starting to remove Discovery's three liquid-fueled shuttle main engines today so a faulty turbopump can be swapped out.Coming soon after the engines had been installed, the work begins with the removal of Engine No. 2 followed by Engine No. 3 and finally Engine No. 1. The faulty pump is in Engine No. 1, and it cannot be removed first when the ship is horizontal due to interference issues with the equipment used to do the job.

The suspect turbopump is connected to shuttle propellant ducting and supported in a fixed position on the orbiter. Engineers noted in a standard torque test that the turbine in the pump was not spinning properly so they recommended swapping it out.

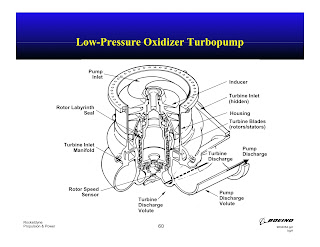

The suspect turbopump is connected to shuttle propellant ducting and supported in a fixed position on the orbiter. Engineers noted in a standard torque test that the turbine in the pump was not spinning properly so they recommended swapping it out.The Low Pressure Oxidizer Turbopump is an axial-flow pump driven by a six-stage turbine that is powered by liquid oxygen. It boosts the pressure of the liquid oxygen from 100 psia to 422 psia, funneling the propellant to a High Pressure Oxidizer Turbopump. The increase in pressure enable the high-pressure pump to operate at higher speeds without running dry. The low-pressure pump, which is about 18 by 18 inches operates at about 5,150 rpm. The high-pressure pump operates at about 28,120 rpm.

A tri-engine removal after installation is a relatively infrequent operation. The last time was in May 2007 when all three engines were pulled from Atlantis is the Kennedy Space Center Vehicle Assembly Building. The removal was required so engineers could perform inspections on main propulsion system feedlines.

NOTE ON IMAGES: The schematic is courtesy of our friends at www.nasaspaceflight.com. Check out the site. NSF Managing Editor and Administrator Chris Bergin and all do a great job. Click to enlarge to top photo, which shows a Pratt and Whitney Rocketdyne technician removing one of three main engines from Discovery for post-flight maintenance and inspections back in May. Photo credit: NASA/Cory Huston.

18 comments:

Should read "Work preformed improperly by AIMAW technicians the first time leads to overtime for same techs...."

These yahoos are just playing the game...they are going to string this out as long as possible using 'accidents and suspicions'as excuses to justify redo work. I would bet that by the time all is said and done that labor costs for 2 final missions will be 3-5 times more than what they could've been. Exact thing happened when Titan program was cancelled....

Anonymous, For your information the orbiter techs are NOT AIMAW.

Yeah right! and it really couldn't be just a bonafide fault thats developed. Things DO go wrong in engineering on this scale you know!.And what if it wasn't picked up during checks,the damn engine would fail in flight potentially causing DISASTER.!! Think about that.!!.

Pratt Turbopumps rock!

This rocketdyne component sux.

Graham, you have to realize that a VAST majority of the people that post on this blog are conspiracy theory loving smack talkers. They just love to trash talk the good work that happens at the space center because they weren't smart enough to get a job out there or were fired from the space center.

Graham...you're half right....problem should've been resolved long BEFORE engines were installed for flight LAST WEEK.....

;)

was the pump bench tested before installation?

Yes, most people posting re: space program...HAVE NO CLUE what goes on at KSC!!!

The pump passed torque checks in the shop but engineering knows that moving the engine from vertical to horizontal to install in the orbiter can cause problems. That's why they always re-perform the pump torque test once the engine is installed. It doesn't happen frequently but it does happen. It is NOT a result of anyone doing their job improperly.

It must be hard for some people to grasp but in the OPF and Engine Shop there are very few Union members. Basically only the people in logistics, crane crew, and high crew are union. Engine Shop and the orbiter Tech and Quality are definitely NOT union. Therefore, it was NOT AIMAW playing games that caused this problem. Your silly name-calling doesn't do anything for your credibility either.

I'd like to have one of those turbos to push gaseous oxygen into my car engine. 8-)

To Anonymous, Yeah i know it tends to be that way with some people posting on here.Shame really though. And thanks for the correction(i don't get everything right). Love what NASA does by the way,always have ever since i was six and saw all the moon landings from 1969 to 1972. I find it a great pity, that your great nations manned space programmes future is in such disaray now.I felt that constellation was a good long term plan to go back out into deep space again.

* The discrepant pump passed all inspections after its last flight. It also passed post-flight torque checks.

* The fact that this happened after engine installation justifies the very reason why post engine installation torque checks are done. The system of checks and rechecks worked as designed.

* This happens so infrequently that special tooling to remove just this pump from position 1 engine was never fabricated, since it was a 1 in 1,000 chance it would happen. Well, that 1 chance popped up now.

* 3 engines will be removed, a pump changed out and an engine retested, and 3 engines will be reinstalled and secured. Total hit on the orbiter schedule: around 10 days start to finish. Not bad. There have been greater schedule hits due to less work.

Anonymous @ 1:32 pm:

That's great detail!

Thanks!

Todd

Problem fixed, job done nice work everyone.Just shows the checks that are done are vital.!

Who cares ?

For anonymous at 5:07. You want to hear about a waste of money. Pratt spent over ten years over 2 billion developing those turbopumps. Rocketdyne could of built a new pump for every flight in the shuttle program, then threw the pumps away after flight and still only spent a tenth of the amount of what Pratt spent on those pumps. Then to make it worse, during developing the pumps, they put metals known to suffer from hydrogen embritlement in the pumps that set the development back a couple of years. Pratt is the worst company in the world. They should of never got the contract to develop the pumps. Then all they did was get the plans for the pump from rocketdyne. Because NASA told rocketdyne to give the plans to Pratt.

Anonymous at 11:22pm:

The pumps that Pratt & Whitney spent over 10yrs/$2B are different pumps - they were the high pressure turbopumps, not the low pressure turbopumps that are mentioned in this article. The SSME has 4 pumps - 2 low pressure ones that feed to 2 high pressure ones - that pump fluids through its systems. The high pressure pumps are MUCH MUCH more complex than the low pressure ones and operate in totally different ways. The high pressure oxidizer turbopump (HPOTP), for example, spins at over 22,000RPM during operation and changes the fluid pressure from ~400psia inlet to over 4,000psia at its discharge. The rest of what you said from the third sentence on is correct. FYI....P&W lost the bid to initially design/build/maintain the SSME over Rocketdyne back in the 1970's, starting 'bad blood' between the two companies. Then, when P&W won the bid to redesign and build those newer high-pressure pumps in the late 1980's as mentioned. Rocketdyne was not part of Pratt & Whitney then, it was part of Rockwell and also later it was part Boeing. Then, in 2006 or so, Rocketdyne was sold by Boeing to Pratt & Whitney. P&W in a roundabout way finally got their SSME.

Post a Comment